JUKI feeder high speed

JUKI feeder can feed 20 times per second, and can change materials without stopping the machine.

JUKI feeder high life

A single feeder can continuously produce more than 10 million points, which solves the problem that feeder maintenance does not require too much maintenance and replacement of parts.

JUKI feeder human-computer dialogue

The number of placements of each feeder can be monitored in real time, and database analysis can be performed.

JUKI feeder high interchangeability

A feeder can be used as 8*2/8*4 for arbitrary switching.

JUKI feeder fine-tuning function

Due to electronic motor control, the feeding distance can be fine-tuned. Solved the problem of asynchronous placement of mechanical feeders for a long time.

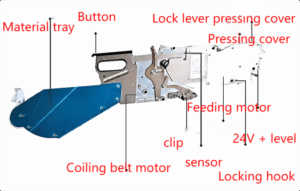

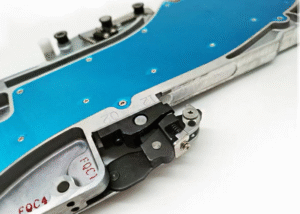

JUKI feeder high security. The safe locking device solves the problem of collision caused by unstable feeder installation, caused by human factors.

| Original | Made in China |

| Material | Aluminum Alloy |

| Model | JUKI2000 Series Electric Feeder, FX series, and 750 and 760 models |

| Application | JUKI,KE Series FX Series |

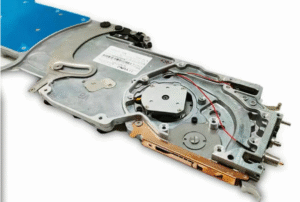

3. High-performance stepper motor

Customized by domestic motor industry quality developers, feeding motor and winding motor, dual motors work together to feed fast, strong and stable.

4. Less material throwing and high precision

The material of the same type of feeder on the market is the best, and it is nickel-plated to prevent rust and oxidation, reducing vibration and wear that cause unstable positioning!

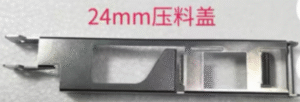

5.Upgraded capping(Pressing cover)

- The structural design fully meets the needs of various materials, especially for special-shaped and difficult-to-cut materials, and has a good solution effect. 2. Made of 304 stainless steel, it is wear-resistant, durable and not easy to damage. 3. Stable feeding, high precision, capping spring can be adjusted according to the thickness of the material. 4. Anti-impact design to prevent the capping from bouncing up and hitting the nozzle rod

6. Intelligence

The self-developed electric feeder is an intelligent chip feeder with automatic return to origin, fine-tuning of material picking position, flexible and fast feeding, and ensuring feeding stability, thereby compensating for the unstable feeding caused by long-term wear of the machine feeder position1

1.Versatility

Replaces all pneumatic feeders. One electric feeder can replace three original pneumatic feeders of different specifications (0201 0402 0603). 12/16 universal to achieve simple switching of different taping pitches:, suitable for almost all series of KE FX chip machines.

2.Super simplicity

No need to power on the installation of the material take-up mechanism to take up the tape simply and directly, so that the material tape can be taken up for a long time without interruption.

3.High cost performance

This product has independent intellectual property rights and can provide timely support services for a long time. Buying one feeder to replace three original feeders greatly reduces costs and the after-sales rate is less than 2%.

4.Feeder Specification

| JUKI | CWEF-JE8 | |

| Size | Length | 684mm |

| Width | 160mm | |

| Thickness | 15mm | |

| Weight | 2.0kg | |

| Main material | Aluminum | |

| SMT Machine type | KE700,KE2000 and FX Series | |

| Can replace feeders | NF,CF,FF,AF,CFR,FFR | |

| Fixed model | Locking | |

| Voltage | DC 24V | |

| Peak current | 0.8A | |

| Average current | 0.4A | |

| Diving mode | Stepping motor | |

| Feeding signal | sensor | |

| Min step angel | 1.8°±5% | |

| Feeding Speed | 12 times/sec | |

| Refueling method | X±0.03mm,Y±0.03mm | |

| Applicable package | 8mm | |

| Drive Roller unit | Upper stripping | |

| Refueling method | No stopping of the machine to receive materials | |

| Error proofing rate | / | |

| Aging test | 100000times without stopping | |

| Life | Over 2 years | |

JUKI 12/16/24mm

| JUKI | CWEF-JE12/16/24 | |

| Size | Length | 684mm |

| Width | 160mm | |

| Thickness | 15mm | |

| Weight | 2.4kg or 2.6kg | |

| Main material | Aluminum | |

| SMT Machine type | KE700,KE2000 and FX Series | |

| Can replace feeders | NF,CF,FF,AF,CFR,FFR | |

| Fixed model | Locking | |

| Voltage | DC 24V | |

| Peak current | 0.8A | |

| Average current | 0.4A | |

| Diving mode | Stepping motor | |

| Feeding signal | sensor | |

| Min step angel | 1.8°±5% | |

| Feeding Speed | 5-12 times/sec | |

| Refueling method | X±0.03mm,Y±0.03mm | |

| Applicable package | 8mm | |

| Drive Roller unit | Upper stripping | |

| Refueling method | No stopping of the machine to receive materials | |

| Error proofing rate | / | |

| Aging test | 100000times without stopping | |

| Life | Over 2 years | |