The Importance of SMT Machines in PCB Assembly Process

PCB assembly is a crucial process in the creation of electronic devices. Printed circuit boards (PCBs) provide a platform for electronic components to be mounted and connected, allowing for the creation of complex electronic devices with high functionality. One critical component of PCB assembly is Surface Mount Technology (SMT) machines. SMT machines have revolutionized PCB assembly, making the process faster, more accurate, and more cost-effective. In this article, we will explore the importance of SMT machines in PCB assembly and how they are used in the process.

What is PCB Assembly?

PCB assembly is the process of creating a printed circuit board (PCB) that is used in electronic devices. The PCB assembly process involves several steps, including the creation of the PCB design, the fabrication of the PCB, the placement of electronic components on the PCB, and the soldering of these components onto the board.

The PCB assembly process can be divided into two main categories: through-hole technology and Surface Mount Technology (SMT).

Through-hole technology involves drilling holes in the PCB and mounting electronic components through these holes. Through-hole technology has been used for many years and is still in use today. However, it has several limitations, including a larger footprint, a lower component density, and higher assembly costs.

Surface Mount Technology (SMT), on the other hand, involves mounting electronic components directly onto the surface of the PCB. SMT technology uses smaller components and a higher component density, allowing for more compact PCB designs. SMT technology has become the preferred method of PCB assembly in many industries.

The Importance of SMT Machines in PCB Assembly

SMT machines play a critical role in the PCB assembly process. SMT machines are used to mount electronic components onto the PCB, and they are a significant improvement over traditional through-hole technology.

SMT machines use a pick-and-place method to mount electronic components onto the PCB. This method involves the use of a robotic arm that picks up electronic components and places them onto the PCB in the correct position.

SMT machines are much faster and more accurate than traditional through-hole technology, as they can place electronic components much closer together. This allows for smaller and more compact PCB designs, which is essential in modern electronics.

SMT machines are also more cost effective than traditional through-hole technology, as they require less manual labor and can produce PCBs at a much faster rate.

How SMT Machines Work

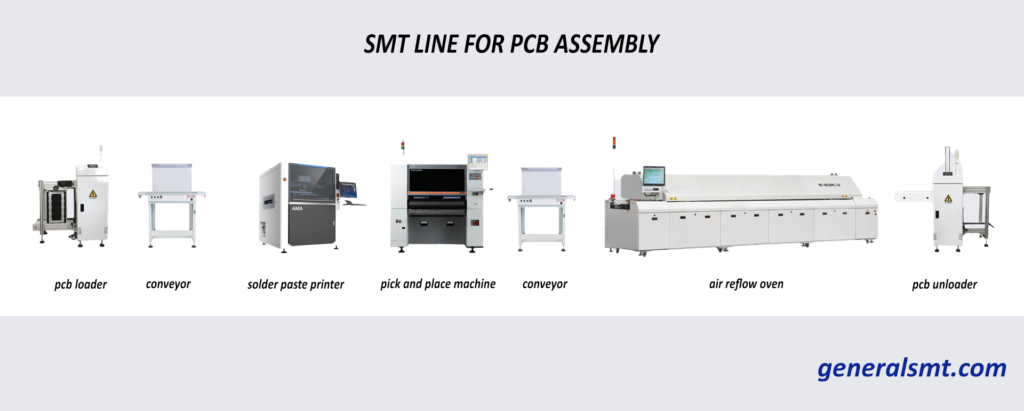

SMT machines use a pick-and-place method to mount electronic components onto the PCB. This process involves several steps:

Step 1: PCB Loading

The first step in the SMT process is to load the PCB onto the machine. The machine uses a conveyor system to move the PCB through the assembly process.

The first step in the SMT process is to load the PCB onto the machine. The machine uses a conveyor system to move the PCB through the assembly process.

Step 2: Component Feeding

Electronic production on SMT line – PCB machine computer chip assembly. Technology Electronics on SMT Line for production of computer chips by SMT Pick and Place machine with Machine Vision System. The next step is to feed electronic components into the machine. The machine uses a component feeder to supply the electronic components to the pick-and-place head.

Step 3: Pick and Place

The pick-and-place head is responsible for picking up electronic components and placing them onto the PCB. The head uses a vacuum to pick up the components and then places them onto the PCB in the correct position.

Step 4: Reflow Soldering

After the electronic components have been placed onto the PCB, the board goes through a reflow soldering process. This process involves heating the board to a high temperature to melt the solder and create a permanent bond between the components and the PCB.

Step 5: Inspection

Once the board has been soldered, it goes through an inspection process to ensure that all components have been placed correctly and that there are no defects.

Once the board has been soldered, it goes through an inspection process to ensure that all components have been placed correctly and that there are no defects.