Table of Contents

Choosing the Right SMT Spare Parts Supplier: Factors to Consider for Reliable and Efficient Equipment Maintenance

Surface mount technology (SMT) is a widely used technology in electronics manufacturing, where electronic components are mounted directly onto a printed circuit board (PCB) without drilling holes. This process of mounting electronic components onto a PCB has revolutionized the electronics industry, making it possible to produce smaller, more efficient, and more reliable electronic devices. However, the SMT process is complex and requires precision equipment to function optimally. As with any other manufacturing process, downtime is costly, and production delays are unacceptable. That is why having high-quality SMT spare parts is critical to the smooth operation of SMT equipment.

SMT spare parts are parts that are used to repair or replace faulty components in SMT machines. These parts are specifically designed to work with SMT equipment, ensuring compatibility and optimal performance. There are several different types of SMT spare parts, including feeders, nozzles, belts, sensors, motors, and valves. Each of these parts plays a vital role in the SMT process, and ensuring that they are of high quality is essential for the production process’s success.

There are several benefits to using high-quality SMT spare parts. Firstly, high-quality parts are designed to be compatible with specific equipment, ensuring optimal performance. This compatibility ensures that the equipment runs smoothly and reduces the risk of failure. Secondly, high-quality parts are manufactured to strict standards and undergo rigorous testing to ensure their reliability and durability. This testing ensures that the parts can withstand the high demands of the SMT process, reducing the risk of failure and downtime. Thirdly, using high-quality parts

(SMT) machines are complex pieces of equipment used in the manufacturing of printed circuit boards (PCBs). Like any machinery, SMT machines require regular maintenance and occasional repair. Therefore, smt spare parts play an important role in keeping the SMT machines running smoothly. Some of the most common spare parts required for SMT machines include:

Nozzles: These are used to pick up components and place them on the PCBs. Nozzles can wear out over time, and it’s important to have spares on hand.

Feeders: Feeders are used to hold components before they are placed on the PCB. SMT machines can have many feeders, each designed to hold a specific component. Having extra feeders on hand can help reduce downtime when a feeder needs to be repaired.

Belts: Belts are used to move the PCBs and the components through the SMT machine. Over time, belts can stretch, crack, or break, so it’s important to have extra belts on hand.

Motors: Motors are used to move the different parts of the SMT machine. If a motor fails, it can cause the machine to stop working properly. Having spare motors on hand can help reduce downtime.

Filters: Filters are used to keep the air inside the SMT machine clean. Dirty filters can lead to contamination of the PCBs and components. Having spare filters on hand is important for maintaining the quality of the PCBs being produced.

Sensors: Sensors are used to detect the position of components and the movement of the PCBs through the SMT machine. If a sensor fails, it can cause the machine to stop working properly. Having spare sensors on hand can help reduce downtime.

These are just a few examples of the spare parts that may be required for an SMT machine. The specific spare parts needed will depend on the make and model of the machine, as well as the specific components being produced.

Nozzles are another critical SMT spare part. The nozzle is responsible for picking up the component from the feeder and placing it on the PCB accurately. Nozzles come in different sizes and shapes to suit the components they handle. They are also made from different materials, including ceramics, plastics, and metals. The nozzle’s size and shape are critical to ensure accurate component placement, and using a poorly sized or shaped nozzle can lead to inaccuracies in placement and ultimately result in defective products

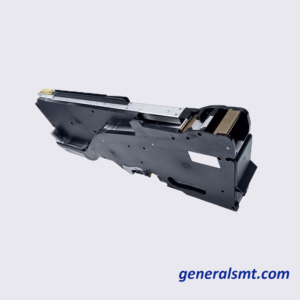

Feeders are an important component of pick and place machines used in SMT (Surface Mount Technology) assembly. They are used to hold and feed electronic components to the pick and place head, allowing for fast and accurate placement of components onto PCBs (Printed Circuit Boards).

Feeders come in several types, including tape feeders, tray feeders, and stick feeders. Tape feeders are the most commonly used type and come in different widths to accommodate different tape sizes. Tray feeders are used for larger components and can hold multiple components at once. Stick feeders are used for components that cannot be loaded onto tape, such as odd-shaped components or those that are too fragile.

When selecting feeders, it’s important to consider factors such as component size and shape, feeder capacity, machine compatibility, and reliability. Different feeders may be required for different component types and sizes. Additionally, the feeder should be compatible with your pick and place machine and able to hold a sufficient number of components to minimize downtime.

Overall, the selection of the right feeder is essential for achieving high levels of efficiency and accuracy in SMT assembly, making it an important consideration for equipment maintenance and repair.

Belts are another critical SMT spare part. They are used to transport the PCB through the machine during the assembly process. Belts must be durable, flexible, and able to withstand the demands of the assembly process. If a belt breaks or becomes damaged during production, it can result in downtime and significant delays in the production process.

Motors and valves are other SMT spare parts used in the machines. Motors are used to drive the various components of the machine, such as feeders, belts, and nozzles. Valves are used to control the flow of air and other gases through the machine, which is essential for the placement process. If a motor or valve fails, it can result in significant delays and downtime.

Sensors are used to detect the presence or absence of components on the PCB. They are essential for ensuring the accuracy of the placement process and preventing errors. There are many different types of sensors available, including optical sensors, mechanical sensors, and proximity sensors. Each type of sensor has its advantages and disadvantages and is suited for specific components.

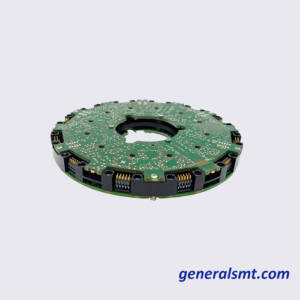

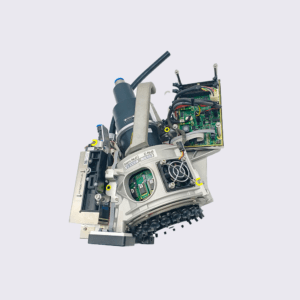

A head for a pick and place machine is the part of the machine that is responsible for picking up a component or part and placing it onto a circuit board or other substrate. The head typically includes a vacuum or suction system that allows it to securely grasp the component and a mechanism for accurately positioning the component onto the target location.

Pick and place machines are commonly used in electronics manufacturing to automate the process of placing components onto circuit boards. The machines can handle a wide range of component sizes and types, and can be programmed to place components at high speeds with extreme accuracy.

There are many different types of heads available for pick and place machines, each designed to handle specific types of components and substrates. Some heads are designed to handle large components, while others are designed for small, delicate parts. The choice of head will depend on the specific needs of the manufacturing process.