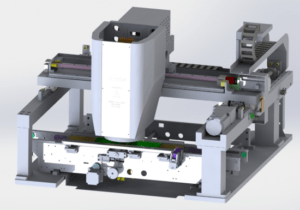

GSMT-510 3D AOI with 12Mpixel coexpress high-speed camera, high-resolution telecentric industrial lens, 4-way moire digital projection head, combined with multi-frequency fringe light to realize 3D image information of components and welding, with a minimum of 8um resolution (standard setting 15umm), it can more accurately and stably detect defects such as IC pin false soldering, part floating height, tin climbing height and so on

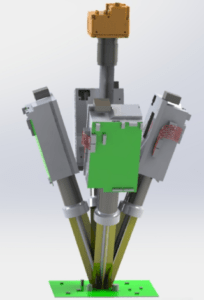

Structure grating system

The N-step phase-shifting algorithm is based on the white light moire fringe technique, providing high inspection accuracy; There are multiple grating options for dealing with light and shadow.

High-precision control platform

The motion platform adopts the Linear motor, which is high-speed, and stable, with no vibration and noise. With the high precision grating closed-loop feedback system, the movement precision can reach 1um.

High-speed Industry camera

Import 12Mp High frame rate industrial camera and Telecentric lens to achieve high-speed photography; Self-owned intellectual property RGBW 4-channel light can get 2D & 3D true color images that look realistic; The GPU parallel processing technique can greatly improve the speed of calculation and detection.

| CATEGORY | ITEM | SPECIFICATION |

| Recognition System | Inspection | The vector image algorithms include logic operation, a distance of luminance boundary, chip tracing, OCR/OCV, luminance/color template matching, color distance, color extraction(RGB & HSV), value-range of luminance, offset of luminance, the minimum variation span of luminance, etc… More than 30 kinds of the most advanced algorithms. |

| Camera | Digital high-speed CCD 12M Pixel camera | |

| Resolution & FOV | 15um FOV 60*45mm □

Or 10um FOV 40*30mm □ Or 8um FOV 32*24mm £ |

|

| Lens | Telecentric Lens | |

| Light | Ring LED light | |

| Projection System | 4 directional projection gratings | |

| 3D height measurement range | 20mm | |

| Per-image Time | <0.5s | |

| Paste Printing Defects | Solder paste printing: Missing, Shift, Insufficient solder; Excessive solder Break, Stain,height,area,volume | |

| Component Defects | Components defects: Missing, Shift skewed, Tombstone,Billboard, Overturned, Reversed polarity, Wrong, Damaged,Coplanarity,Height defect,Size | |

| Solder Defects | Solder joint defects: Insufficient solder, Excessive solder, Solder bridge, Copper stain | |

| Wave Soldering Inspect | Overflow,Insufficient,Short,Excess solder, Solder void | |

| Minimum component | 01005& 0.3mm pitch(15um) | |

| Mechanical System | PCB Conveyor | Left to right or right to left (One key shift) |

| PCB fixing: bottom-up, PCB warp correction. | ||

| Automatic PCB loading and unloading, Adjustable clearance, Conforming SMEMA standard. | ||

| Conveyor clearance: 900±20mm | ||

| PCB Size | 50×50mm-510×460mm | |

| PCB Thickness | 0.5mm – 5.0mm | |

| PCB Warp Tolerance | <2mm(Fixture-assisted deformation correction) | |

| Component Clearance | TOP≤50mm, BOT≤50mm(customized for special requirements) | |

| Driver | AC servo,camera moves in the directions of X/Y. | |

| Orientation | <10um | |

| Moving Speed | Standard:500mm/s,Max:800mm/s | |

| Soft System | Operation System | Microsoft Windows 10 X64 |

| Characteristic | Basis on Vector analysis algorithm, integrated variety of software algorithms of Color Extraction、 Luminance Extraction 、Color Distance,for SMT components and the position of the solder joints , appearance , accurate positioning and analysis accurately eliminate all kinds of bad points | |

| Operation | Graphic programming, Chinese, English | |

| Programming | CAD、handwork programming, Support offline programming(Optional) | |

| Computer | CPU INTEL I9, RAM 128GB,HDD:1TB SSD+2TB HDD | |

| Display | 21 inch TFT | |

| Network | Multi machine control | The operator can control multi same machines in the control terminal |

| Network | NG adaptable, check and correct PCBA defects at repair station | |

| Communication port | SMEMA, RS232,RJ45 | |

| Other | Air Supply | 0.5MPA.80cm³/min |

| Machine Dimensions | 1390×1400×1600mm | |

| Weight | ~1100kg | |

| Working Environment | Temperature10-40℃, humidity 30-80% RH |

Reviews

There are no reviews yet.